Color coated steel coil

Color coated plate, also known as color steel plate or color plate in the industry. Color coated steel plate is a type of plate material obtained on a continuous unit using cold-rolled strip steel, galvanized strip steel (electroplated and hot-dip galvanized) as substrates, surface pre-treatment (degreasing, cleaning, and chemical treatment), roller coating method, one or more layers of liquid coating, and baking and cooling.

Category:

Color coated steel coil

Key words:

Product description

Product Introduction

Color coated plate, also known as color steel plate or color plate in the industry. Color coated steel plate is a type of plate material obtained on a continuous unit using cold-rolled strip steel, galvanized strip steel (electroplated and hot-dip galvanized) as substrates, surface pre-treatment (degreasing, cleaning, and chemical treatment), roller coating method, one or more layers of liquid coating, and baking and cooling.

Due to the fact that coatings can come in various colors, it is customary to refer to coated steel plates as colored coated steel plates. Due to the fact that the coating is carried out before the steel plate is formed, it is called pre coated steel plate in foreign countries.

Color-coated steel plate is an organic coating applied to the surface of steel, which has the advantages of beautiful appearance, bright color, high strength, good corrosion resistance, convenient processing and forming, and can also allow users to reduce costs and reduce pollution.

Coated steel plate has lightweight, beautiful and good anti-corrosion performance, and can be directly processed, it provides a new type of raw material for the construction industry, shipbuilding industry, vehicle manufacturing industry, home appliance industry, electrical industry, etc., and has played a good effect of replacing wood with steel, efficient construction, energy saving, and pollution prevention. It is mainly used in building roofs, walls, steel structure workshops, home appliance boards, purification and clean workshops and other fields.

The color coated steel plate using galvanized steel plate as the substrate, in addition to the zinc protection, the organic coating on the zinc layer plays a covering and isolating effect, which can prevent the steel plate from rusting, and the service life is longer than that of galvanized steel plate, according to reports, the service life of coated steel plate is 50% longer than that of galvanized steel plate.

However, in different regions and different parts of use, the service life of colored coated sheets with the same amount of galvanization, the same kind of paint, and the same coating thickness will be very different. For example, in industrial or coastal areas, due to the action of sulfur dioxide gas or salts in the air, the rate of corrosion is accelerated and the service life is affected. In the rainy season, the coating will be corroded quickly if it is soaked by rainwater for a long time, or in the parts where the temperature difference between day and night is too large and easy to condense, and the service life will be reduced. Buildings or factories made of color-coated steel sheets often have a longer service life when they are often washed by rainwater, otherwise they are affected by the action of sulfur dioxide gas, salts and dust. Therefore, when designing, if the slope of the roof is greater, it is less likely to accumulate dust and other dirt, and the longer the service life; For those areas or areas that are not regularly washed by rainwater, they should be washed with water regularly.

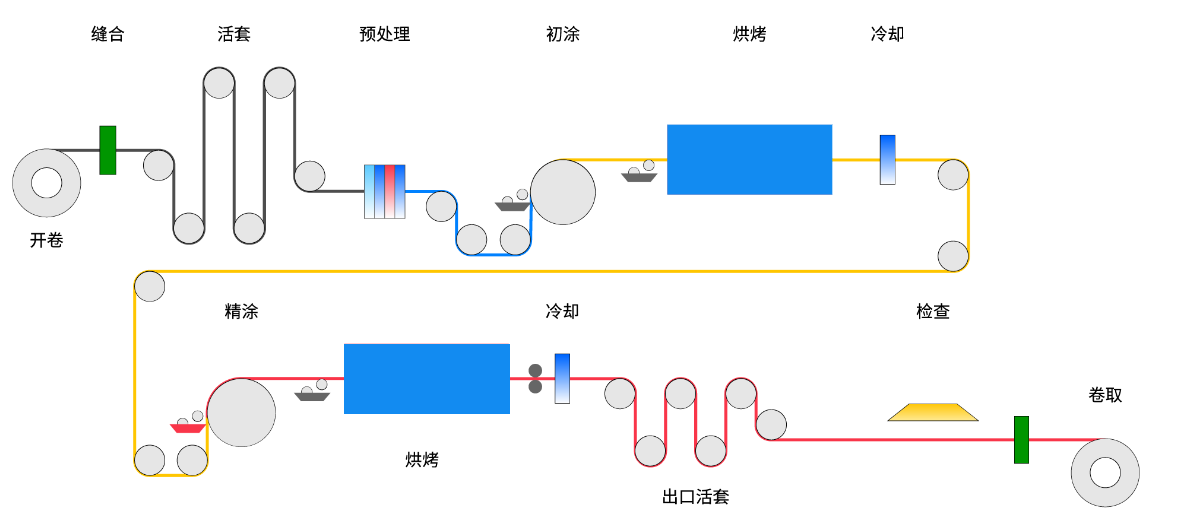

Production process

Product Specifications:

|

Coil thickness |

0.13-3.5mm |

|

Coil width |

100-1500mm |

|

Coil inner diameter |

Φ508mm/Φ610mm |

|

Coil outer diameter |

Φ800-1500mm |

|

Coil weight |

2-10Tons |

|

Zinc layer |

40-275g/㎡ |

|

Coating structure |

2/2 front double coated/reverse double coated |

|

|

2/1 front double coat / back single coat |

|

color |

RAL standard international color card, conventional colors sea blue, white gray, crimson, wall gray, silver gray; It can be colored according to the customer's sample |

|

Varnish film thickness |

Top coat 10-25 μm, back paint 3-10 μm |

|

paint |

PE ordinary polyester color-coated sheet, SMP silicon modified polyester color-coated sheet, HDP high weather-resistant color-coated sheet, PVDF fluorocarbon color-coated sheet |

|

Quality Certifications |

GB/T19001-2016/ISO9001:2015 |

|

wrap |

Packed according to customer's requirements |

Test Standards

|

Film thickness/DFT |

Magnetic film thickness gauge |

|

chromatic aberration |

There is no color difference in the batch visually; The colorimeter is less than or equal to 0.5 |

|

luster |

40-60% or depending on customer requirements |

|

T-bend test |

The front is less than or equal to 3T; The back side is less than or equal to 4T |

|

Pencil hardness |

H / coil steel pencil |

|

Impact test |

Greater than or equal to 9J |

|

MEK butanone test |

100 times/butanone or coin |