Galvanized steel coil

Galvanized sheet refers to a steel sheet with a layer of zinc on its surface. Galvanizing is an economical and effective method of rust prevention that is often used, and about half of the world's zinc production is used in this process. Galvanized steel plate is to prevent the surface of the steel plate from being corroded and prolong its service life, and a layer of metal zinc is coated on the surface of the steel plate, and this galvanized steel plate is called galvanized plate.

Category:

Galvanized steel coil

Key words:

Product description

Product Introduction

Galvanized sheet refers to a steel sheet with a layer of zinc on its surface.

Galvanizing is an economical and effective method of rust prevention that is often used, and about half of the world's zinc production is used in this process. Galvanized steel plate is to prevent the surface of the steel plate from being corroded and prolong its service life, and a layer of metal zinc is coated on the surface of the steel plate, and this galvanized steel plate is called galvanized plate.

According to the production and processing methods, it can be divided into the following categories:

(1) Hot-dip galvanized steel sheet. A thin steel plate is immersed in a molten zinc bath so that a layer of zinc adheres to its surface. At present, it is mainly produced by continuous galvanizing process, that is, the coiled steel plate is continuously immersed in the plating tank with zinc melted to make galvanized steel plate;

(2) Alloyed galvanized steel plate. This steel plate is also made by the hot-dip method, but immediately after it is slotted, it is heated to about 500°C to form an alloy film of zinc and iron. This galvanized sheet has good coating adhesion and weldability;

(3) Electro-galvanized steel plate. The electroplating method is used to manufacture this galvanized steel sheet, which has good machinability. However, the coating is thinner, and the corrosion resistance is not as good as that of hot-dip galvanized sheet;

(4) Single-sided and double-sided differential galvanized steel sheets. Single-sided galvanized steel sheet, i.e. a product that is galvanized on only one side. In welding, painting, anti-rust treatment, processing, etc., it has better adaptability than double-sided galvanized sheet. In order to overcome the shortcomings of uncoated zinc on one side, there is another galvanized sheet coated with a thin layer of zinc on the other side, that is, double-sided differential galvanized sheet;

(5) Alloy and composite galvanized steel plate. It is a steel plate made of zinc and other metals such as aluminum, lead, zinc, etc., made of alloys and even composite plating. This kind of steel plate not only has excellent anti-rust performance, but also has good coating performance;

In addition to the above five types, there are also color galvanized steel sheets, printed and coated galvanized steel sheets, PVC laminated galvanized steel sheets, etc. However, at present, the most commonly used is still hot-dip galvanized sheet.

Uses: Galvanized sheet strip products are mainly used in construction, light industry, automobile, agriculture, animal husbandry and fishery and commercial industries. Among them, the construction industry is mainly used to manufacture anti-corrosion industrial and civil building roof panels, roof grilles, etc.; It is used in the light industry to manufacture household appliance shells, civil chimneys, kitchen utensils, etc., and the automobile industry is mainly used to manufacture corrosion-resistant parts for cars; Agriculture, animal husbandry and fishery are mainly used as grain storage and transportation, frozen processing utensils for meat and aquatic products, etc.; It is mainly used in commerce as a storage, transportation, packaging utensils and so on.

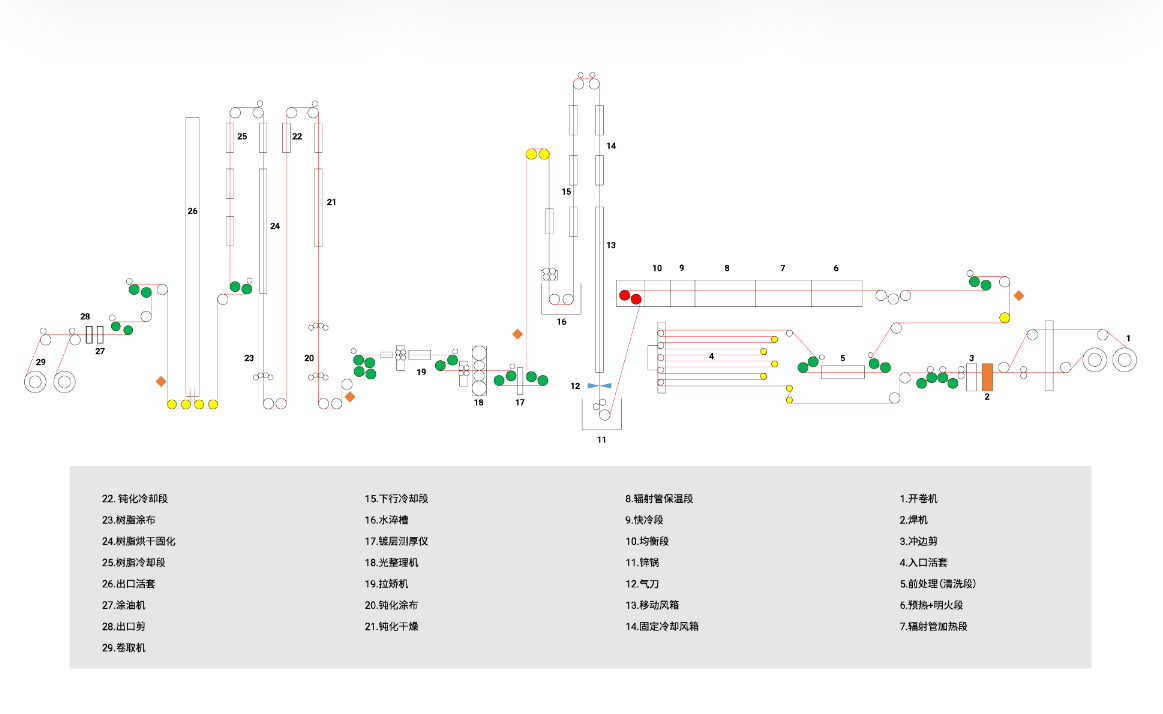

Production process

Zinc flower is a surface morphology of hot-dip pure zinc coil, when the steel strip passes through the zinc pot, the surface is coated with liquid zinc, and then in the process of natural solidification of the zinc layer, the zinc grain nucleus grows and zinc flower appears. The name "zinc flower" comes from the fact that the complete zinc crystals show a snowflake-like shape, which can be said to be very vivid.

The generation of zinc sparks is affected by the composition of the coating and the cooling rate/mode, when the hot-dip galvanized sheet products first emerged, the steel mill could not control the size of the zinc sparks as they wanted, and the surface of the hot-dip pure galvanized coils produced had zinc sparks of various sizes and shapes, which once made people think that "the ones with zinc sparks are hot-dip galvanized".

Classification of zinc flowers

Surface treatment

|

The surface treatment of the zinc layer |

Description of use |

|

Chromatic acid passivation (C) |

It is used for surface treatment after hot plating of high-strength steel plate to reduce white rust during transportation and storage |

|

Chromium-free passivation (C5) |

It is required to limit the use of surface treatment methods such as hexavalent chromium in passivation solution, which is harmful to the environment and human body |

|

Fingerprint Resistant (N) |

The surface treatment after the passivation process plays a lubricating role in the processing process, preventing fingerprint stains during operation and premature blackening of the surface during use |

|

Chromium-free fingerprint resistant (N5 |

The surface treatment method after the Kaneka process plays a lubricating role in the processing process, prevents the fingerprint marks during operation from staining, prevents the surface from being blackened prematurely during use, and at the same time requires the restriction of fingerprint resistance Hexavalent chromium that is harmful to the environment and the human body |

|

oil |

After the Kanka process, surface treatments were added to further reduce rust during long-distance transportation and long-term storage |

Product Specifications:

|

Coil thickness |

0.12-6.0mm |

|

Coil width |

100-1500mm |

|

Coil inner diameter |

Φ508mm |

|

Coil outer diameter |

Φ800-1500mm |

|

Coil weight |

4-8Tons |

|

Zinc layer |

40-275g/㎡ |

|

strength |

G250/G280/G300/G320/G350/G550/DX51D/DX52D/DX53D |

|

paint |

PE ordinary polyester color-coated sheet, SMP silicon modified polyester color-coated sheet, HDP high weather-resistant color-coated sheet, PVDF fluorocarbon color-coated sheet |

|

Quality Certifications |

GB/T19001-2016/ISO9001:2015 |

|

wrap |

Packed according to customer's requirements |

Test Standards

|

Inspection items |

Technical requirements |

|

appearance |

1) Mainly check whether there are obvious defects such as discoloration, oxidation, rust and other defects on the surface of the steel plate, and evaluate the uniformity and consistency of the plating layer. The coating is uniform, there are no obvious stripes, corrosion, scars, etc., and there is no deformation of the substrate 2) The model and specification meet the inspection requirements |

|

Packaging requirements |

The outer packaging must be marked with product name, model, code, quantity, etc., and the handwriting must be clear The packaging must have a waterproof and rust-proof effect, |

|

size |

Thickness (mm): Standard thickness ± 0.05 |

|

Width (mm): standard width before cutting, The standard width after cutting ± 0.5 |

|

|

Zinc layer weight (double-sided) g/㎡ |

Three-point experimental average |

|

Acid and alkali resistance test |

The galvanized steel sheet is soaked in an acid-base solution for a certain period of time, and then the corrosion of the surface is observed. The standard requires that the steel plate should not have obvious corrosion. |

|

Yield strength Rel MPa |

140-300 |

|

*Tensile strength Rm MPa |

270-420 |

|

*Elongation after break: A80mm% |

≥26 |

|

★ Salt spray test |

In accordance with the "MWE-WWQM099 Salt Attraction Test Operation Instructions", it is required to pass the continuous spray 21-hour salt spray test |

|

Basis for inspection |

GB/T 2518-2008 |

|

1. The project marked with the "" number is the type test, which is implemented in accordance with the reliability test and inspection plan, and the project marked with "※" ★ is sent for inspection once every six months. |

|